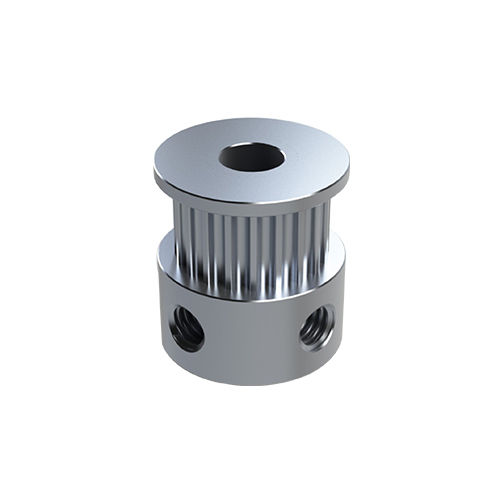

5mm Pitch Timing Pulleys

Price 500 INR/ Piece

5mm Pitch Timing Pulleys Specification

- Application

- Automation Systems, Industrial Machinery, CNC Machines, Robotics

- Number Of Grooves

- Available with various grooves/tooth counts (e.g. 10, 16, 20, up to 48)

- Bearing Type

- Plain Bore (No Integrated Bearing)

- Mounting Type

- Flange Mount / Set Screw / Clamp Bush

- Features

- Precision Machined, Corrosion Resistant, High Durability, Anti-Slip Design, Smooth Operation

- Bore

- Available in multiple bore sizes (customization possible)

- Power Source

- Mechanical, driven by motors or shafts

- Diameter

- 16mm to 120mm (Depending on the tooth count) Millimeter (mm)

- Chain Length

- Not applicable (uses timing belts, not chains)

- Pulley Type

- Timing Pulley

- Usage

- Industrial

- Material

- Aluminum / Steel

- Size

- Various Sizes Available

- Product Type

- Timing Pulley

- Color

- Different Available

- Customization

- OEM orders accepted for diameter, bore, and tooth count

- Tooth Width

- 10mm / 15mm / 20mm / custom

- Pitch

- 5mm

- Surface Finish

- Polished / Anodized for corrosion resistance

- Profile

- T5 and other metric timing profiles available

- Belt Compatibility

- Suitable for 5mm pitch timing belts (T5, AT5)

- Tooth Material

- Hardened steel or anodized aluminum

- Hub Type

- Solid hub or pilot bore available

- Temperature Range

- -20C to +80C

- Precision Grade

- DIN / ISO Standard Manufacturing

- Lubrication

- Not required for normal operation

- Packaging

- Box / Poly Bag / Export Standard Packaging

5mm Pitch Timing Pulleys Trade Information

- Minimum Order Quantity

- 20 Pieces

- FOB Port

- AHMEDABAD

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard Packing & As Per Client's Requirement.

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001 :2015

About 5mm Pitch Timing Pulleys

- Condition - New

- Material - Stainless Steel

- Quality - Premium

| PART NO | PULLEY SIZE | PULLEY TYPE | MATERIAL | NO. OF TEETH | PD | A | HD | PW | L | MIM BORE (D) | MAX BORE | APPROX WEIGHT (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N0379 | 12-5M-15 | 1F | STEEL | 12 | 19.10 | 23 | 12 | 20.5 | 26 | 4 | 7 | 0.03 |

| N0380 | 14-5M-15 | 1F | STEEL | 14 | 22.28 | 25 | 13 | 20.5 | 26 | 6 | 8 | 0.04 |

| N0381 | 15-5M-15 | 1F | STEEL | 15 | 23.87 | 28 | 16 | 20.5 | 26 | 6 | 10 | 0.05 |

| N0382 | 16-5M-15 | 1F | STEEL | 16 | 25.46 | 28 | 16.5 | 20.5 | 26 | 6 | 11 | 0.06 |

| N0383 | 18-5M-15 | 1F | STEEL | 18 | 28.65 | 32 | 20 | 20.5 | 26 | 6 | 13 | 0.09 |

| N0384 | 20-5M-15 | 1F | STEEL | 20 | 31.83 | 36 | 23 | 20.5 | 26 | 6 | 14 | 0.12 |

| N0385 | 21-5M-15 | 1F | STEEL | 21 | 33.42 | 38 | 24 | 20.5 | 26 | 6 | 15 | 0.14 |

| N0386 | 22-5M-15 | 1F | STEEL | 22 | 35.01 | 38 | 25.5 | 20.5 | 26 | 6 | 16 | 0.15 |

| N0387 | 24-5M-15 | 1F | STEEL | 24 | 38.20 | 42 | 27 | 20.5 | 28 | 6 | 18 | 0.19 |

| N0388 | 26-5M-15 | 1F | STEEL | 26 | 41.38 | 44 | 30 | 20.5 | 28 | 6 | 20 | 0.23 |

| N0389 | 28-5M-15 | 1F | STEEL | 28 | 44.56 | 48 | 30.5 | 20.5 | 28 | 6 | 20 | 0.26 |

| N0390 | 30-5M-15 | 1F | STEEL | 30 | 47.75 | 51 | 35 | 20.5 | 28 | 6 | 24 | 0.32 |

| N0391 | 32-5M-15 | 1F | STEEL | 32 | 50.93 | 54 | 38 | 20.5 | 28 | 8 | 26 | 0.35 |

| N0392 | 36-5M-15 | 1F | STEEL | 36 | 57.30 | 60 | 38 | 20.5 | 28 | 8 | 26 | 0.43 |

| N0393 | 40-5M-15 | 1F | STEEL | 40 | 63.66 | 70 | 38 | 20.5 | 28 | 8 | 26 | 0.52 |

| N0394 | 44-5M-15 | 1F | STEEL | 44 | 70.03 | 75 | 45 | 20.5 | 30 | 8 | 33 | 0.70 |

| N0395 | 48-5M-15 | 1F | STEEL | 48 | 76.39 | 80 | 50 | 20.5 | 30 | 8 | 38 | 0.82 |

| N0396 | 60-5M-15 | 1F | STEEL | 60 | 95.49 | 100 | 65 | 20.5 | 30 | 8 | 53 | 1.33 |

| N0397 | 72-5M-15 | 1F | STEEL | 72 | 114.59 | 120 | 80 | 20.5 | 30 | 8 | 68 | 1.95 |

Precision Engineering for Industrial Applications

Our 5mm pitch timing pulleys are crafted to exacting DIN and ISO standards, ensuring dependable operation in automation systems, CNC machines, robotics, and industrial machinery. The robust construction reduces downtime and improves efficiency, making them ideal for any critical drive application requiring accuracy and durability.

Customizable Solutions for Your Needs

We offer a wide spectrum of sizes, tooth counts, and widths to fit your specific requirements. With available options for hub type, bore size, and mounting, our pulleys can be tailored for specialized machinery or OEM projects. Every component is meticulously machined for seamless integration and optimal power transmission.

Corrosion Resistance and Long-Term Performance

Choose between anodized aluminum or hardened steel for superior durability and corrosion protection. Our pulleys feature polished or anodized surfaces, enabling smooth operation even in demanding environments. Designed to last, they require no lubrication for normal use, reducing maintenance and operating costs.

FAQs of 5mm Pitch Timing Pulleys:

Q: How do I select the right timing pulley size and profile for my application?

A: To choose the correct timing pulley, consider the belt pitch (5mm), tooth width, required profile (T5 or AT5), bore size, and tooth count based on your power transmission needs and compatibility with your existing timing belts and shafts. Customizations for diameter or bore are available as per your machinery requirements.Q: What materials and surface finishes are available for these timing pulleys?

A: Our timing pulleys are manufactured from hardened steel or anodized aluminum for robust performance and resistance to corrosion. Surface finishes include polished or anodized options, ensuring durability and longevity even under industrial conditions.Q: When is lubrication needed for these timing pulleys?

A: Under normal operation, lubrication is not required due to the precision machining and surface treatments applied. This keeps maintenance minimal, but for extreme duty cycles or environments beyond standard specifications, please consult us for further recommendations.Q: Where can these timing pulleys be used?

A: These pulleys are suitable for a wide range of industrial applications, including CNC machines, automation systems, robotics, and other mechanical assemblies that use 5mm pitch metric timing belts, particularly T5 or AT5 profiles.Q: What benefits do your timing pulleys offer compared to standard pulleys?

A: Our timing pulleys deliver precision machined accuracy, anti-slip design, corrosion resistance, and customizable options. They provide smooth, quiet, and reliable power transmission, supporting higher efficiency and less maintenance than many conventional pulleys.Q: How can I place an order for customized specifications?

A: For OEM or custom orders involving specific diameters, bore sizes, tooth counts, or mounting types, please contact us with your detailed requirements. Our team will provide tailored solutions and international export-standard packaging to meet your projects demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Pulley Category

3mm Pitch Timing Pulleys

Price 300.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Mounting Type : Set Screw / Clamp

Usage : Industrial

Material : Other, Aluminum Alloy

Number Of Grooves : As per selected model

5mm Pitch Timing Pulleys

Price 300.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Mounting Type : Center Bore / Keyway / Set Screw

Usage : Industrial

Material : Other, Aluminum, Steel

Number Of Grooves : From 12 up to 72 teeth (varies by model)

14mm Pitch Timing Pulleys

Price 300 INR / Piece

Minimum Order Quantity : 20 Pieces

Mounting Type : Shaft Mount

Usage : Industrial

Material : Other, Highgrade Aluminum Alloy / Steel

Number Of Grooves : Multiple Grooves Available (Depending on Size)

14mm Pitch Timing Pulleys

Price 400 INR / Piece

Minimum Order Quantity : 20 Pieces

Mounting Type : Pilot Bore or Finished Bore with Keyway

Usage : Industrial

Material : Other, High Grade Aluminum Alloy

Number Of Grooves : Various (1 to 5 grooves as per design)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS