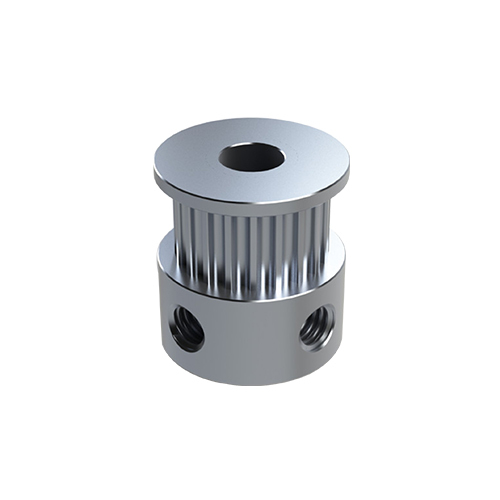

Stainless Steel Silver 14mm Pitch Timing Pulleys

Price 400 INR/ Piece

Stainless Steel Silver 14mm Pitch Timing Pulleys Specification

- Power Source

- Mechanical (Driven by Belt & Motor)

- Application

- Power Transmission in Industrial Machinery

- Mounting Type

- Pilot Bore or Finished Bore with Keyway

- Features

- Corrosion Resistant, Precision Machined, High Durability

- Pulley Type

- 14mm Pitch Timing Pulley

- Load Capacity

- Up to 3000 kg depending on size and material Kilograms (kg)

- Number Of Grooves

- Various (1 to 5 grooves as per design)

- Bore

- Customizable (Based on requirement, typically 10mm to 60mm)

- Bearing Type

- Not Included (Fits Standard Shaft/Bearing)

- Usage

- Industrial

- Material

- High Grade Aluminum Alloy

- Size

- Various Sizes Available

- Product Type

- Timing Pulleys

- Color

- Different Available

- Teeth Profile

- Synchronous, Accurate Tooth Engagement

- Fastening Method

- Setscrew/Clamp/Timing Bush

- Temperature Range

- -40C to +150C

- Surface Finish

- Hard Anodized / Polished

- Dynamic Balancing

- Provided for High-Speed Operation

- Hub Type

- Standard, Extended, Flanged

- Packaging

- Corrugated Box with Protective Wrapping

- Maximum RPM

- Up to 5000 rpm (depends on diameter/material)

- Pitch

- 14mm (Standard)

- Lead Time

- 2 to 6 weeks (based on size & quantity)

Stainless Steel Silver 14mm Pitch Timing Pulleys Trade Information

- Minimum Order Quantity

- 20 Pieces

- FOB Port

- AHMEDABAD

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- STANDAR PACKGING AND AS PER CUSTOMER REQURIMENT

- Main Domestic Market

- All India

- Certifications

- ISO 9001:20015 ,CE

About Stainless Steel Silver 14mm Pitch Timing Pulleys

- Condition - New

- Material - Stainless Steel

- Quality - Premium

| PART NO | PULLEY SIZE | PULLEY TYPE | MATERIAL | NO. OF TEETH | PD | A | HD | ID | PW | L | MIM BORE (D) | MAX BORE | APPROX WEIGHT (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N0577 | 28-14M-170 | 1F | STEEL | 28 | 124.78 | 128 | 100 | - | 187 | 202 | 32.0 | 67.0 | 14.80 |

| N0578 | 30-14M-170 | 1F | STEEL | 30 | 133.69 | 138 | 100 | - | 187 | 202 | 32.0 | 67.0 | 16.70 |

| N0579 | 32-14M-170 | 1F | STEEL | 32 | 142.60 | 154 | 100 | - | 187 | 202 | 32.0 | 67.0 | 19.40 |

| N0580 | 34-14M-170 | 1F | STEEL | 34 | 151.52 | 160 | 100 | - | 187 | 202 | 32.0 | 67.0 | 21.85 |

| N0581 | 36-14M-170 | 1F | STEEL | 36 | 160.43 | 168 | 100 | - | 187 | 202 | 32.0 | 80.0 | 25.20 |

| N0582 | 38-14M-170 | 1F | STEEL | 38 | 169.34 | 184 | 120 | - | 187 | 202 | 32.0 | 90.0 | 28.40 |

| N0583 | 40-14M-170 | 1F | STEEL | 40 | 178.25 | 188 | 135 | - | 187 | 202 | 32.0 | 90.0 | 32.26 |

| N0584 | 48-14M-170 | 1F | STEEL | 48 | 213.90 | 226 | 150 | - | 187 | 202 | 32.0 | 90.0 | 39.50 |

| N0585 | 64-14M-170 | 3F | STEEL | 64 | 285.21 | 296 | 150 | 240 | 187 | 187 | 32.0 | 90.0 | 54.00 |

| N0586 | 80-14M-170 | 3 | CAST IRON | 80 | 356.51 | - | 150 | 314 | 187 | 187 | 32.0 | 108.0 | 69.40 |

| N0587 | 90-14M-170 | 3 | CAST IRON | 90 | 401.07 | - | 150 | 358 | 187 | 187 | 32.0 | 108.0 | 71.30 |

| N0588 | 112-14M-170 | 3 | CAST IRON | 112 | 499.11 | - | 150 | 456 | 187 | 187 | 32.0 | 108.0 | 88.00 |

| N0589 | 144-14M-170 | 3 | CAST IRON | 144 | 641.71 | - | 165 | 600 | 187 | 187 | 32.0 | 108.0 | 113.00 |

| N0590 | 192-14M-170 | 3 | CAST IRON | 192 | 855.62 | - | 165 | 813 | 187 | 187 | 32.0 | 108.0 | 140.00 |

Precision Engineering for High-Performance

Meticulously crafted for synchronous and precise tooth engagement, the 14mm pitch pulleys ensure flawless power transmission in demanding industrial machinery. Each pulley is precision machined from premium aluminum alloy, offering enhanced durability, corrosion resistance, and a smooth operational experience over a wide temperature range.

Versatile Design & Customizable Options

Choose from standard, extended, or flanged hub types to suit diverse mounting requirements. Customizable bore diameters (10mm to 60mm) and a selection of pulley diameters (40mm to 500mm) facilitate integration into various setups. Fastening is secure and adaptable, with setscrew, clamp, or timing bush options, supporting grooves configurations from 1 to 5.

Certified Quality & Reliable Delivery

Produced under stringent DIN/ISO QA standards, each timing pulley ensures compliance, safety, and exceptional performance. Packaged securely in corrugated boxes, they are dispatched as per order volume, with lead times ranging from 2 to 6 weeks. Exported and supplied across India, these pulleys offer reliability where it counts.

FAQs of 14mm Pitch Timing Pulleys:

Q: How do I select the correct 14mm pitch timing pulley for my application?

A: Determine the belt type (T-14 or AT-14), hub style (standard, extended, flanged), required bore size, and number of grooves. Also, factor in operating environment, material strength, and load capacity. Our pulleys are customizable for different diameters and applications.Q: What benefits does the hard anodized or polished finish provide?

A: Both surface finishes enhance corrosion resistance and longevity. Hard anodizing offers superior wear protection, while polished surfaces reduce friction and facilitate easy maintenance under high-speed or abrasive conditions.Q: When should I specify dynamic balancing for timing pulleys?

A: Dynamic balancing is recommended for high-speed operations exceeding 3000 rpm or in precision power transmission systems to ensure vibration-free performance and longevity of machinery.Q: Where can these pulleys be used in industrial setups?

A: They are ideal for power transmission in various industrial machinery, including conveyor systems, printing equipment, and automation lines, providing reliable synchronous motion.Q: What is the typical lead time for order fulfillment?

A: Lead times range from 2 to 6 weeks, depending on the quantity and size specifications. Custom orders may require additional processing time for specific bore or groove configurations.Q: How do I mount the timing pulley onto shafts or bearings?

A: Pulleys can be fitted with setscrews, clamps, or timing bushes and are available in pilot bore or finished bore with keyway variants. Ensure compatibility with standard shafts or bearings for secure mounting.Q: What process ensures product quality and compliance?

A: Every pulley undergoes precision machining, dynamic balancing, and rigorous quality assurance under DIN and ISO standards, ensuring optimal performance and reliability in industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Pulley Category

14mm Corrosion Free SS Pitch Timing Pulleys

Price 300 INR / Piece

Minimum Order Quantity : 20 Pieces

Size : Various Sizes Available

Features : AntiCorrosion Coating, Precise Tooth Profile, Durable, Low Noise Operation

Pulley Type : 14mm Pitch Timing Pulley

Mounting Type : Pilot Bore / Finished Bore / Taper Lock as per requirement

Pitch Timing Pulleys

Price 300.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Size : Customized

Features : Corrosion Resistant, High Durability, Precision Engineering

Pulley Type : Timing Pulley

Mounting Type : Shaft Mount

8mm Corrosion-free Alluminium/ Steel Pitch Timing Pulleys

Price 300.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Size : Various Sizes Available

Features : Corrosion Resistant, Durable, High Precision, Wear Resistant

Pulley Type : 8mm Pitch Timing Pulley

Mounting Type : Shaft/Hub Mount

Industrial Timinng Pulley

Price 300 INR / Piece

Minimum Order Quantity : 20 Pieces

Size : Customized

Features : Corrosion Resistant, Durable, High Precision

Pulley Type : Timing Pulley

Mounting Type : Flange/Hub Mounted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free