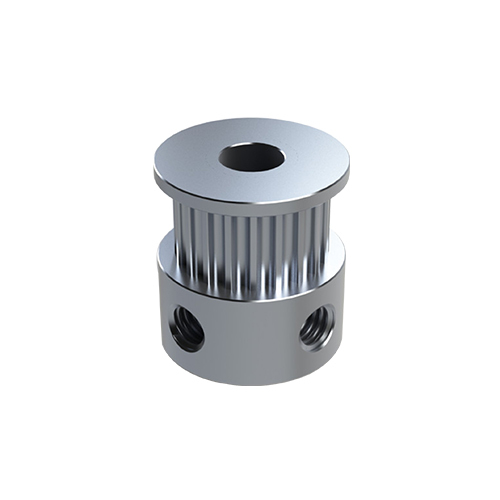

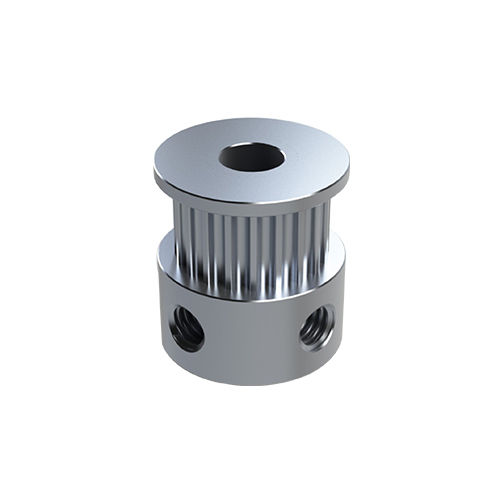

Pitch Timing Pulleys

Price 300.00 INR/ Piece

Pitch Timing Pulleys Specification

- Application

- Industrial Machinery

- Mounting Type

- Shaft Mount

- Bore

- Customized

- Load Capacity

- Heavy Duty

- Features

- Corrosion Resistant, High Durability, Precision Engineering

- Pulley Type

- Timing Pulley

- Bearing Type

- Ball Bearing

- Power Source

- Mechanical

- Number Of Grooves

- Single/Multiple (As per requirement)

- Diameter

- Customized

- Usage

- Industrial

- Material

- Aluminium

- Size

- Customized

- Product Type

- Timing Pulley

- Color

- Different Available

- Packaging Type

- Box/Carton

- Hardness

- 50-70 HRC

- Maximum Speed

- Up to 6000 RPM

- Tooth Profile

- HTD, T, AT, XL, L (As per specification)

- Operating Temperature

- -20°C to 120°C

- Surface Finish

- Anodized/Polished

- Pitch Type

- Metric/Imperial

Pitch Timing Pulleys Trade Information

- Minimum Order Quantity

- 20 Pieces

- FOB Port

- AHMEDABAD

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard Packing & As Per Client's Requirement.

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Pitch Timing Pulleys

- Condition - New

- Material - Stainless Steel

- Quality - Premium

| PART NO | PULLEY SIZE | PULLEY TYPE | MATERIAL | NO. OF TEETH | PD | A | HD | PW | L | MIM BORE (D) | MAX BORE | APPROX WEIGHT (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N0300 | 10-3m-06 | 0F | ALUMINIUM | 10 | 9.55 | 13.00 | 13.00 | 7.20 | 14.50 | 4.00 | 4.00 | 0.004 |

| N0301 | 12-3M-06 | 0F | ALUMINIUM | 12 | 11.46 | 15.00 | 15.00 | 7.20 | 14.50 | 4.00 | 6.00 | 0.006 |

| N0302 | 14-3M-06 | 0F | ALUMINIUM | 14 | 13.37 | 16.00 | 16.00 | 7.20 | 14.050 | 4.00 | 7.00 | 0.008 |

| N0303 | 15-3M-06 | 0F | ALUMINIUM | 15 | 14.32 | 17.50 | 17.50 | 7.20 | 14.50 | 4.00 | 8.00 | 0.010 |

| N0304 | 16-3M-06 | 1F | ALUMINIUM | 16 | 15.28 | 18.00 | 10.00 | 9.80 | 17.50 | 4.00 | 6.50 | 0.008 |

| N0305 | 18-3M-06 | 1F | ALUMINIUM | 18 | 17.19 | 20.00 | 11.00 | 9.80 | 17.50 | 6.00 | 7.00 | 0.009 |

| N0306 | 20-3M-06 | 1F | ALUMINIUM | 20 | 19.10 | 23.00 | 12.00 | 9.80 | 17.50 | 6.00 | 8.00 | 0.012 |

| N0307 | 21-3M-06 | 1F | ALUMINIUM | 21 | 20.05 | 25.00 | 13.00 | 9.80 | 17.50 | 6.00 | 8.50 | 0.014 |

| N0308 | 36-2M-06 | 1F | ALUMINIUM | 22 | 21.01 | 25.00 | 13.00 | 9.80 | 17.50 | 6.00 | 8.50 | 0.015 |

| N0309 | 24-3M-06 | 1F | ALUMINIUM | 24 | 22.92 | 25.00 | 13.00 | 9.80 | 17.50 | 6.00 | 8.50 | 0.017 |

| N0310 | 26-3M-06 | 1F | ALUMINIUM | 26 | 24.83 | 28.00 | 16.00 | 9.80 | 17.50 | 6.00 | 10.50 | 0.022 |

| N0311 | 28-3M-06 | 1F | ALUMINIUM | 28 | 26.74 | 32.00 | 18.00 | 9.80 | 17.50 | 6.00 | 11.50 | 0.027 |

| N0312 | 30-3M-06 | 1F | ALUMINIUM | 30 | 28.65 | 32.00 | 20.00 | 9.80 | 17.50 | 6.00 | 12.70 | 0.030 |

| N0313 | 32-3M-06 | 1F | ALUMINIUM | 32 | 30.56 | 36.00 | 22.00 | 9.80 | 17.50 | 6.00 | 14.00 | 0.040 |

| N0314 | 36-3M-06 | 1F | ALUMINIUM | 36 | 34.38 | 38.00 | 26.00 | 10.30 | 18.00 | 6.00 | 17.00 | 0.060 |

| N0315 | 40-3M-06 | 1F | ALUMINIUM | 40 | 38.20 | 42.00 | 28.00 | 10.30 | 18.00 | 6.00 | 18.50 | 0.070 |

| N0316 | 44-3M-06 | 1F | ALUMINIUM | 44 | 42.02 | 48.00 | 3300 | 10.30 | 18.00 | 6.00 | 22.50 | 0.080 |

| N0317 | 48-3M-06 | 1F | ALUMINIUM | 48 | 45.84 | 52.00 | 33.00 | 10.30 | 18.00 | 8.00 | 22.50 | 0.080 |

| N0318 | 60-3M-06 | 1F | ALUMINIUM | 60 | 57.30 | 61.00 | 44.00 | 10.30 | 18.60 | 8.00 | 24.00 | 0.150 |

| N0319 | 72-3M-06 | 1F | ALUMINIUM | 72 | 68.75 | 74.00 | 50.00 | 10.30 | 18.60 | 8.00 | 40.00 | 0.210 |

Versatile Timing Pulleys for Industrial Needs

Our timing pulleys are meticulously manufactured to accommodate a broad range of industrial machinery. With customizable diameters, bores, and groove counts, they ensure precise fitment and optimal performance. Advanced surface treatments like anodizing and polishing enhance corrosion resistance and longevity even in demanding environments.

Elevated Performance and Reliability

Operating within a wide temperature window and speeds up to 6000 RPM, these pulleys maintain high hardness (50-70 HRC) for superior durability. Their robust aluminium construction supports heavy-duty loads, ensuring dependable power transmission and minimal maintenance downtime.

Custom Engineering and Application

Whether your project demands specific tooth profiles, mounting styles, or packaging solutions, our in-house engineering team delivers tailored designs. From single to multiple grooves and diverse color options, every pulley is precision-engineered to meet unique industrial requirements and maximize efficiency.

FAQs of Pitch Timing Pulleys:

Q: How do I determine the correct pitch type and tooth profile for my application?

A: The selection depends on your machinerys requirements and power transmission needs. We offer metric and imperial pitch types with HTD, T, AT, XL, and L profiles. Our technical team can help you identify the optimal configuration for efficient operation in your specific industrial environment.Q: What benefits does the anodized or polished surface finish provide?

A: An anodized or polished surface finish enhances the pulleys resistance to corrosion and wear, prolongs service life, and maintains consistent performance even under harsh operating conditions or frequent use.Q: When should I consider using a customized size or bore for a timing pulley?

A: Custom sizes or bores are ideal when your machinery has unique shaft diameters, space constraints, or specific load and speed requirements. Customization ensures a precise fit, improved performance, and minimizes installation challenges.Q: Where can these timing pulleys be used?

A: Our timing pulleys are designed for integration in a wide range of industrial machinery, including automation systems, conveyor equipment, and heavy-duty mechanical drives, making them suitable for diverse sectors.Q: What is the process for ordering and customizing a timing pulley?

A: You can submit your specifications for size, bore, color, tooth profile, number of grooves, and surface finish. Our engineering team reviews and confirms your requirements before manufacturing, ensuring a tailored solution packaged securely in boxes or cartons for delivery.Q: How does the pulley maintain performance at high speeds and varying temperatures?

A: Constructed from durable aluminium and precision-engineered with ball bearings, the pulley operates reliably at speeds up to 6000 RPM and across temperatures from -20C to 120C, ensuring consistent torque transmission in demanding environments.Q: What advantages does this timing pulley offer over standard alternatives?

A: Our pulleys provide high durability, corrosion resistance, heavy-duty load handling, and precision engineering. Customization options and strict quality control make them a superior choice for specialized industrial and mechanical power transmission needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Pulley Category

14mm Pitch Timing Pulleys

Price 300 INR / Piece

Minimum Order Quantity : 20 Pieces

Application : Synchronous Power Transmission in Industrial Machinery

Product Type : Timing Pulleys

Color : Different Available

Bore : Other, Custom Machined (Standard and Tapered Available)

5mm Pitch Timing Pulleys

Price 300.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Application : Power Transmission, Linear Motion, Automation, Industrial Machinery

Product Type : Timing Pulley

Color : Different Available

Bore : Other, Customizable (Available in various metric and inch sizes)

3mm Pitch Timing Pulleys

Price 300.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Application : Power Transmission in Industrial Machines

Product Type : Timing Pulley

Color : Different Available

Bore : Other, Customizable (as per shaft size)

5mm Pitch Timing Pulleys

Price 400 INR / Piece

Minimum Order Quantity : 20 Pieces

Application : Power Transmission, Stepper Motors, CNC Machines

Product Type : Timing Pulleys

Color : Different Available

Bore : Other, Customizable (as per requirement)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS