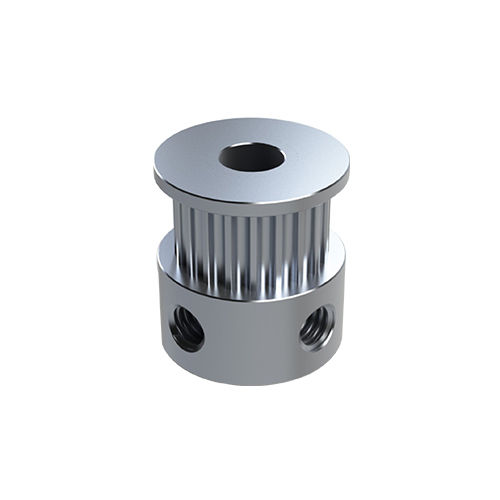

2mm Pitch Timing Pulleys

2mm Pitch Timing Pulleys Specification

- Bore

- Customized (as per requirement)

- Number Of Grooves

- Single or Multiple (as per design)

- Pulley Type

- 2mm Pitch Timing Pulley

- Mounting Type

- Shaft Mount

- Features

- High Precision, Anti-Corrosion, Durable, Lightweight

- Diameter

- As per Specification/Customized

- Application

- Robotics, Automation Equipment, 3D Printers

- Power Source

- Mechanical

- Load Capacity

- Varies as per size and material

- Usage

- Industrial

- Material

- Aluminum Alloy

- Size

- Customized

- Product Type

- Timing Pulley

- Color

- Different Available

2mm Pitch Timing Pulleys Trade Information

- Minimum Order Quantity

- 20 Pieces

- FOB Port

- AHMEDABAD

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard Packing & As Per Client's Requirement.

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About 2mm Pitch Timing Pulleys

ï

- Condition - New

- Material - Stainless Steel

- Quality - Premiumï

ï

| Part No | Pulley Size | Pulley Type | Material | No. Of Teeth | Pd | A | Hd | Pw | L | MIM Bore (D) | Max Bore | Approx Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N1187 | 16-2M-06 | 0F | ALUMINIUM | 16 | 10.19 | 15.00 | 15.00 | 8.50 | 16.00 | 4.00 | 4.00 | 0.01 |

| N1188 | 18-2M-06 | 0F | ALUMINIUM | 18 | 11.46 | 16.00 | 16.00 | 8.50 | 16.00 | 4.00 | 6.00 | 0.01 |

| N1189 | 20-2M-06 | 0F | ALUMINIUM | 20 | 12.73 | 16.00 | 16.00 | 8.50 | 16.00 | 4.00 | 7.00 | 0.01 |

| N1190 | 22-2M-06 | 0F | ALUMINIUM | 22 | 14.01 | 17.50 | 17.50 | 8.50 | 16.00 | 4.00 | 8.00 | 0.01 |

| N1191 | 24-2M-06 | 1F | ALUMINIUM | 24 | 15.28 | 20.00 | 10.00 | 11.00 | 16.00 | 4.00 | 6.50 | 0.01 |

| N1192 | 28-2M-06 | 1F | ALUMINIUM | 28 | 17.83 | 25.00 | 11.00 | 11.00 | 16.00 | 4.00 | 7.00 | 0.01 |

| N1193 | 30-2M-06 | 1F | ALUMINIUM | 30 | 19.10 | 25.00 | 12.00 | 11.00 | 16.00 | 4.00 | 8.00 | 0.02 |

| N1194 | 32-2M-06 | 1F | ALUMINIUM | 32 | 20.37 | 25.00 | 14.00 | 11.00 | 16.00 | 5.00 | 8.50 | 0.02 |

| N1195 | 36-2M-06 | 1F | ALUMINIUM | 36 | 22.92 | 28.00 | 16.00 | 11.00 | 16.00 | 5.00 | 8.50 | 0.02 |

| N1196 | 40-2M-06 | 1F | ALUMINIUM | 40 | 25.46 | 32.00 | 18.00 | 11.00 | 16.00 | 5.00 | 11.00 | 0.03 |

| N1197 | 42-2M-06 | 1F | ALUMINIUM | 42 | 26.74 | 32.00 | 18.00 | 11.00 | 16.00 | 5.00 | 11.50 | 0.03 |

| N1198 | 44-2M-06 | 1F | ALUMINIUM | 44 | 28.01 | 37.00 | 18.00 | 11.00 | 16.00 | 5.00 | 12.70 | 0.03 |

| N1199 | 48-2M-06 | 1F | ALUMINIUM | 48 | 30.56 | 37.00 | 20.00 | 11.00 | 16.00 | 5.00 | 14.00 | 0.03 |

| N1200 | 60-2M-06 | 1F | ALUMINIUM | 60 | 38.20 | 44.00 | 24.00 | 11.00 | 16.00 | 5.00 | 18.50 | 0.04 |

| N1201 | 72-2M-06 | 1F | ALUMINIUM | 72 | 45.84 | 52.00 | 15.00 | 11.00 | 16.00 | 6.00 | 22.50 | 0.05 |

Precision Engineering for Diverse Applications

Designed for optimal performance, our 2mm pitch timing pulleys are ideal for applications ranging from industrial automation to 3D printing. Custom options ensure compatibility with specific systems, while high precision and minimal backlash help deliver smooth and reliable motion transfer. The anti-corrosion, durable construction means longevity even in demanding environments.

Customizable Solutions Tailored to Your Needs

Clients can specify teeth count, diameter, hub type, bore size, and grooves according to their project requirements. Choose from GT2, STD, or other tooth profiles to match your synchronous belt system. With options for anodized finishes and multiple color choices, the pulleys support a variety of technical and aesthetic demands.

Exceptional Durability and Easy Maintenance

Crafted from robust aluminum alloy, our timing pulleys resist oil, abrasion, and corrosion, supporting use in harsh industrial settings. Low maintenance requirements mean reduced downtime and operational costs. Lightweight yet strong, they maintain high load capacities across a range of sizes.

FAQs of 2mm Pitch Timing Pulleys:

Q: How do I choose the right 2mm pitch timing pulley for my machine?

A: When selecting a timing pulley, consider your applications required pitch, tooth profile (GT2, STD, or custom), number of teeth, bore size, hub/flange type, and groove configuration. Customization options let you match specifications closely to your belt drive system for optimal performance.Q: What materials and finishes are available for these timing pulleys?

A: Our pulleys are manufactured from high-tensile aluminum alloy, ensuring a lightweight yet durable product. Surface finishes include anodized or smooth, with multiple color options to suit your preference or system design.Q: Where can these 2mm pitch pulleys be used?

A: They are widely used in robotics, 3D printers, industrial automation equipment, and various mechanical systems that require precise synchronous movement and low backlash. Their robust construction suits both professional and industrial environments.Q: Can the pulley dimensions and features be customized?

A: Yes, all key specificationssuch as number of teeth, diameter, bore size, hub/flange presence, and number of groovescan be tailored to your requirements, ensuring the pulley perfectly matches your projects technical demands.Q: What benefits do these pulleys offer for industrial applications?

A: These pulleys combine high precision, low backlash, high tensile strength, and resistance to oil and abrasion. Their lightweight design ensures easy handling and installation, while their low maintenance reduces operational effort and downtime.Q: How do I mount the pulley onto a shaft?

A: The pulleys are designed for shaft mounting and can be provided with customized bore sizes. Installation generally involves sliding the pulley onto the shaft and securing it using the specified mounting hardware.Q: What maintenance is required for these timing pulleys?

A: Minimal maintenance is needed due to the pulleys durable surface finish and resistance to oil and abrasion. Periodic inspection for wear or alignment is usually sufficient to ensure reliable operation over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Timing Pulley Category

14mm Pitch Timing Pulleys

Price 300 INR / Piece

Minimum Order Quantity : 20 Pieces

Load Capacity : Designed for Heavy Loads

Diameter : Various Diameters Available (According to Requirement)

Application : Industrial Machinery, Conveyors, Automation

14mm Pitch Timing Pulleys

Price Range 300.00 - 500.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Load Capacity : Varies Based on Size and Material

Diameter : Customizable (According to Number of Teeth and Pitch)

Application : Power Transmission, Conveyor Systems, Industrial Automation

3mm Pitch Timing Pulleys

Price Range 300.00 - 500.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Load Capacity : Up to 50 kg

Diameter : 10 mm to 60 mm (Depending on Model)

Application : Automation Equipment, CNC Machinery, Conveyor Systems

14mm Pitch Timing Pulleys

Price Range 200.00 - 1000.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Load Capacity : Up to 3000 kg depending on size and material

Diameter : Multiple Options (Standard from 40mm up to 500mm)

Application : Power Transmission in Industrial Machinery

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free