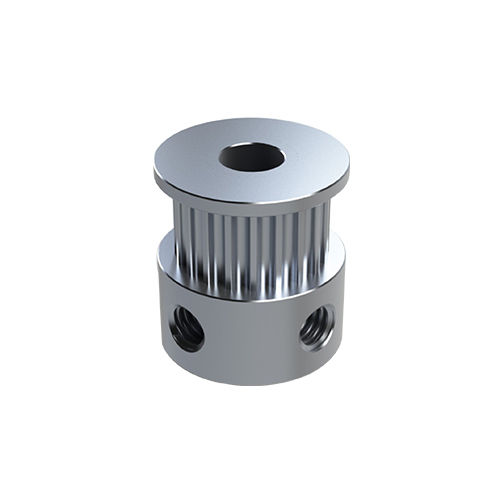

About 8mm Pitch Timing Pulleys

Condition New

Material Stainless Steel

Quality Premium

PART NO PULLEY SIZE PULLEY TYPE MATERIAL NO OF TEETH PD A HD PW L MIM BORE D MAX BORE APPROX WEIGHT kg

N0440 188M30 1F STEEL 18 4583 49 33 38 50 10 19 055

N0441 208M30 1F STEEL 20 5092 57 38 38 50 10 24 064

N0442 228M30 1F STEEL 22 5602 60 43 38 50 12 29 069

N0443 248M30 1F STEEL 24 6112 66 45 38 50 12 30 084

N0444 268M30 1F STEEL 26 6621 70 48 38 50 12 32 100

N0445 288M30 1F STEEL 28 7130 75 50 38 50 15 34 112

N0446 308M30 1F STEEL 30 7639 83 55 38 50 15 36 132

N0447 328M30 1F STEEL 32 8149 87 60 38 50 15 40 153

N0448 348M30 1F STEEL 34 8658 91 70 38 50 15 46 180

N0449 368M30 1F STEEL 36 9167 97 75 38 50 15 50 199

N0450 388M30 1F STEEL 38 9677 102 75 38 50 15 50 227

N0451 408M30 1F STEEL 40 10186 106 75 38 50 15 50 240

N0452 448M30 1F STEEL 44 11205 120 75 38 50 15 50 280

N0453 488M30 1F STEEL 48 11223 128 75 38 50 15 50 320

N0454 568M30 1F STEEL 56 14260 150 90 38 50 15 54 560

N0455 648M30 1F STEEL 64 16297 168 90 38 50 15 54 650

N0456 728M30 1F STEEL 72 18335 192 95 38 50 15 54 810

N0457 808M30 2 CAST IRON 80 20372 100 180 38 50 15 54 510

N0458 908M30 2 CAST IRON 90 22918 100 204 38 50 15 54 570

N0459 1128M30 2 CAST IRON 112 28521 100 254 38 50 18 54 680

N0460 1448M30 2 CAST IRON 144 36669 100 336 38 50 20 54 930

N0461 1688M30 2 CAST IRON 168 42781 100 400 38 50 20 60 1140

N0462 1928M30 2 CAST IRON 192 48892 100 7460 38 50 20 60 1600

Versatile Profile and Design

Our 8mm Pitch Timing Pulleys feature a vast selection of profilesT AT HTD GT or even tailormade to your needs With customizable teeth count diameters and number of grooves these pulleys adapt to a variety of industrial drive configurations ensuring compatibility and performance in automation and conveyor setups

Reliable Performance in Demanding Environments

Engineered to endure operating temperatures from 20C to 90C these pulleys use highquality aluminum or steel for optimal strength and corrosion resistance Their precision manufacturing meets ISO standards providing smooth and accurate power transmission for key industrial applications

Flexible Mounting and Customization

Choose from pilot bore taper lock or customized hub types with both standard and custom bores available These pulleys can be mounted directly to shafts or via hubs providing flexible installation for diverse machinery requirements OEM services and a range of color finishes ensure a tailored solution for your project

FAQs of 8mm Pitch Timing Pulleys

Q How do I select the correct 8mm Pitch Timing Pulley for my application

A Selecting the appropriate pulley involves matching the pitch 8mm profile T AT HTD GT or custom number of teeth and required diameter to your timing belt and system specifications Consider your load capacity mounting type shaft or hub and environmental conditions to ensure compatibility Our team can assist with customization based on your requirements

Q What types of timing belts are compatible with these pulleys

A These pulleys are designed for synchronous timing belts with an 8mm pitch They accommodate various belt profiles including T AT HTD and GT ensuring reliable and accurate transmission across different industrial applications

Q Where can these 8mm Pitch Timing Pulleys be used

A They are ideally suited for industrial environments such as conveyor systems automation machinery and other mechanical drives where precise power transmission and durability are critical Their robust construction also makes them suitable for use in challenging operating temperatures and demanding applications

Q What is the process for ordering a customized timing pulley

A To order a customized pulley simply provide your design specificationsprofile number of teeth diameter bore size hub type material preference and required finish Our OEM service handles design manufacturing and quality assurance ensuring the end product meets ISO tolerance standards and your unique requirements

Q How does the pulley benefit my industrial system

A These pulleys offer high strength accurate power transmission and corrosion resistance contributing to improved efficiency and reduced maintenance in your machinery The ability to customize ensures optimal performance for any specific industrial setup

Q When should I opt for a pilot bore or taper lock hub type

A Pilot bore hubs allow for further machining to fit specific shafts offering flexibility for custom installations Taper lock hubs provide easy installation and removal ideal for frequent maintenance or quick changeovers making them suitable in highusage industrial settings

Q What are the advantages of sourcing timing pulleys from a manufacturer in India

A Sourcing from an Indian manufacturer ensures access to competitive pricing highquality materials strict adherence to ISO standards and efficient export services Our experience as exporters manufacturers and suppliers enables us to deliver reliable products worldwide

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS