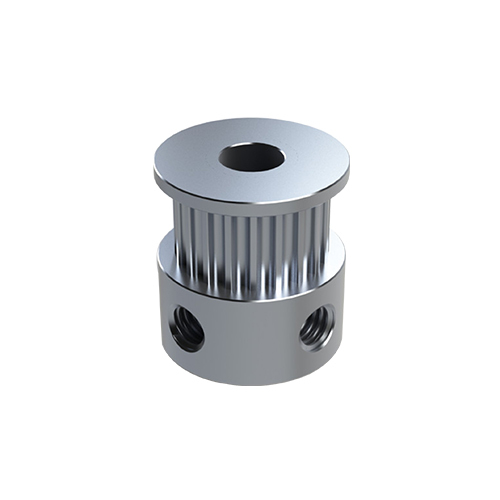

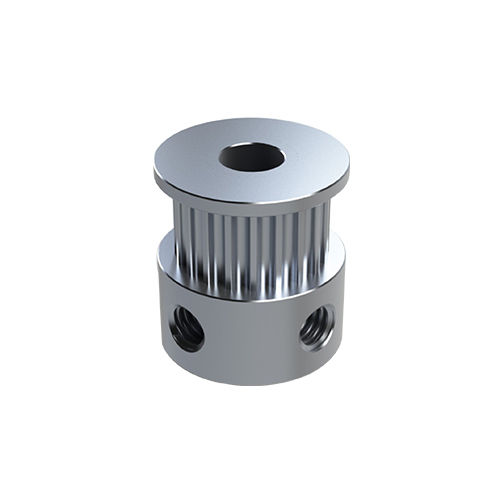

About 3mm Stainless Steel Pitch Timing Pulleys

Condition New

Material Stainless Steel

Quality Premium

PART NO PULLEY SIZE PULLEY TYPE MATERIAL NO OF TEETH PD A HD PW L MIM BORE D MAX BORE APPROX WEIGHT kg

N0320 103M09 0F ALUMINIUM 10 955 1300 1300 1020 1750 400 400 0005

N0321 123M09 0F ALUMINIUM 12 1146 1500 1500 1020 1750 400 600 0007

N0322 143M09 0F ALUMINIUM 14 1337 1600 1600 1020 1750 400 700 0009

N0323 153M09 0F ALUMINIUM 15 1432 1750 1750 1020 1750 400 800 0011

N0324 163M09 1F ALUMINIUM 16 1528 1800 1000 1280 2060 400 650 0009

N0325 183M09 1F ALUMINIUM 18 1719 2000 1100 1280 2060 600 700 0011

N0326 203M09 1F ALUMINIUM 20 1910 2300 1300 1280 2060 600 800 0014

N0327 213M09 1F ALUMINIUM 21 2005 2500 1300 1280 2060 600 850 0017

N0328 223M09 1F ALUMINIUM 22 2101 2500 1300 1280 2060 600 850 0018

N0329 243M09 1F ALUMINIUM 24 2292 2500 1300 1280 2060 600 850 0020

N0330 263M09 1F ALUMINIUM 26 2483 28 16 1280 2060 600 1050 0027

N0331 283M09 1F ALUMINIUM 28 2674 3200 1800 1280 2060 600 1150 0033

N0332 303M09 1F ALUMINIUM 30 2865 3200 2000 1280 2060 600 1270 0038

N0333 323M09 1F ALUMINIUM 32 3056 3600 2200 1280 2060 600 1400 0046

N0334 363M09 1F ALUMINIUM 36 3438 3800 2600 1340 2220 600 1700 0062

N0335 403M09 1F ALUMINIUM 40 3820 4200 2800 1340 2220 600 1850 0077

N0336 443M09 1F ALUMINIUM 44 4202 4800 3300 1340 2220 600 2250 0097

N0337 483M09 1F ALUMINIUM 48 4584 5200 3300 1340 2220 800 2550 0120

N0338 603M09 1F ALUMINIUM 60 5730 6100 4400 134 2220 800 2400 062

N0339 723M09 1F ALUMINIUM 72 6875 7400 5000 1340 2220 800 4000 0260

Precision Engineering for Industrial Demands

Each 3mm Pitch Timing Pulley is manufactured with meticulous attention to detail offering a precise HTDSTD tooth profile This ensures seamless synchronization between belts and pulleys delivering minimal slippage and accurate power transmission The set screw mounting and customizable hub and bore configurations provide adaptable installation for various industrial environments supporting smooth operation in demanding conditions

Robust Materials for Extended Lifespan

Built with either anodized aluminum or zincplated steel these timing pulleys exhibit excellent resistance to corrosion and abrasion Their heavyduty construction allows them to handle load capacities of up to 50 kg making them especially suitable for highstress applications like CNC machinery and automated conveyor systems This choice of materials ensures a lengthy service life even in challenging workspaces

FAQs of 3mm Pitch Timing Pulleys

Q How are 3mm pitch timing pulleys typically installed in industrial equipment

A 3mm pitch timing pulleys are installed using set screws and often feature customizable bores or hubs for easy integration Depending on your machinery requirements you can select a pulley with the appropriate number of teeth bore size and mounting type to ensure a secure and precise fit

Q What belt types and tooth profiles are these pulleys compatible with

A These pulleys are designed to work with synchronous or timing belts and support both HTD High Torque Drive and STD Synchronous Timing Drive tooth profiles This compatibility ensures they can be used in a wide range of standard timing belt applications

Q When should aluminum versus steel pulleys be chosen

A Aluminum pulleys are ideal for applications demanding lightweight components and corrosion resistance such as in delicate automation systems Steel pulleys are better suited to heavyduty or highload environments where strength and durability are prioritized such as in CNC machinery

Q Where can these timing pulleys be used in industrial settings

A They are widely used in automation equipment CNC machining and conveyor systems Due to their heavyduty build and precise tooth profiles they perform reliably in industries such as manufacturing packaging and logistics

Q What processes are used to ensure pulley durability and accuracy

A The pulleys are manufactured using precision machining anodizing or zinc plating to enhance surface resistance against wear and corrosion Tolerances are controlled to within 001 mm guaranteeing consistent performance and long service life

Q How does the surface finish benefit the application

A Anodized and zincplated finishes protect against environmental factors like moisture and chemical exposure effectively reducing wear and rust This ensures optimal efficiency and reduces maintenance requirements over prolonged use

Q What are the key benefits of using these timing pulleys in automation and CNC machinery

A Their precise tooth alignment robust construction and resistance to abrasion and corrosion contribute to smooth reliable power transmission This minimizes downtime enhances equipment efficiency and extends the operational lifespan of your systems

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free